-

Recommendation: *****

-

To B or C: B2B

-

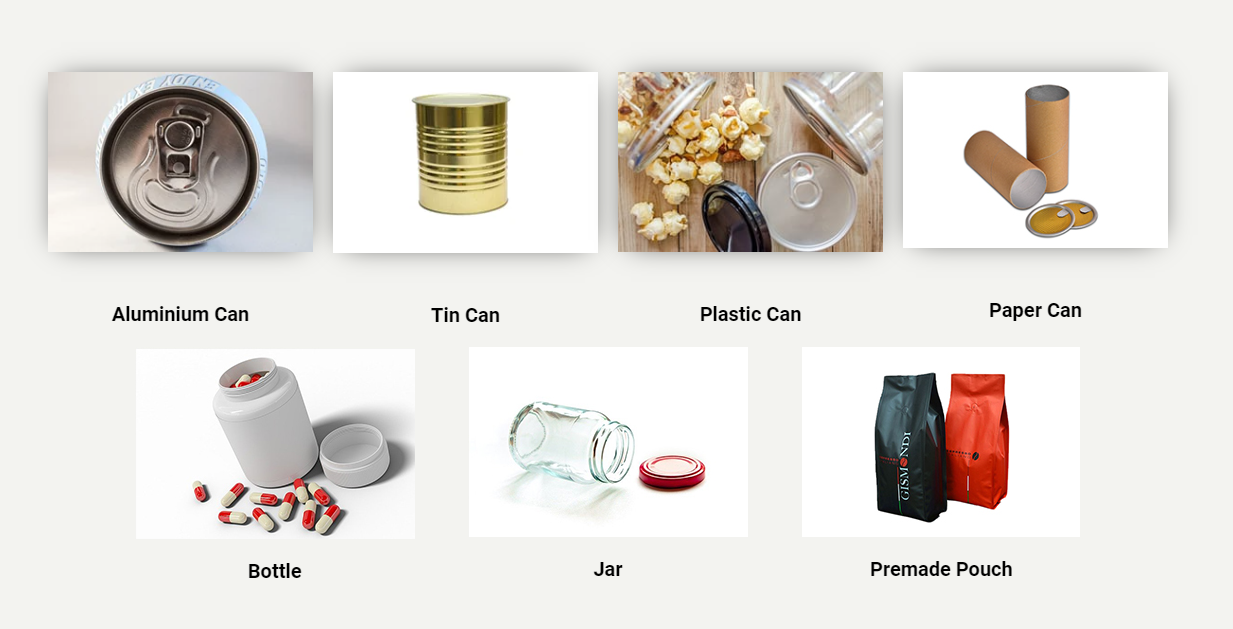

Main Products: Can seamers, canning machines, can labeling machines

About LevaPack

LevaPack, which has existed since 2018, shot to the top of the canning machine manufacturing industry on the strength of fourteen years of expertise from its technical team in production and research on can packaging equipment. The company is located within Conghua District of Guangzhou City in Guangdong Province, a strategic geographical position that has fostered positive market perception.

At LevaPack’s ultra-modern premises there are a professional R&D team and sales force guaranteeing that customers get finely-tuned machines at reasonable prices. Their primary focus is in can sealing and packaging machinery development, manufacturing and sale with solutions such as filling, labeling as well as coding for cans. They have different types of can seamers including low-speed, high-speed servo high speed semi-automatic vacuum nitrogen can seamer among others designed to suit different production requirements.

LevaPack upholds continuous improvement, integrity, efficiency, innovation and pragmatism through its robust marketing network across China and present in more than 30 countries globally. As such they seek to be recognized globally by becoming an acclaimed leader in the business sector for their customers with great service provisions and quality deliveries in the field of sealing machines worldwide.

Exceptional Production Capacity

Apart from its modern 4000 square meter facility in Guangzhou, LevaPack has the exceptional production capacity. The facility has state-of-the-art CNC machinery including milling machines, lathes, and grinding units that guarantee manufacturing precision and efficiency. To respond promptly and effectively to customer needs each month, the company maintains a stockpile of no less than 80 standard machines.

LevaPack conducts a standardized production process through an ERP system. It involves comprehensive analysis of customer requirements, detailed solution design, explicit planning of production, part’s procurement, precise equipment assembly including programming for stability testing before final inspection. Before shipping out any machine, they go through thorough overload testing to ensure safety as well as reliability, thus reducing chances of breakdowns while extending the lifespan of the machine.

To make sure minimal defects and high standards are maintained in the process with a fault rate of less than 2% and yearly average reduction in maintenance costs by 30%, this is how we have designed our production process. Thus, it is committed to quality and efficiency so that they can produce sturdy machines with superior performance that can meet tough requirements for food industry or chemical sector among others.

LevaPack has strong production capabilities coupled with strict quality control systems ensuring that it supplies clients with top-quality equipment which promotes efficiency in operations enhancing productivity as well. This commitment to excellence positions LevaPack as one of leading manufacturers of can making machine on worldwide market.

High-Quality Components

LevaPack’s can filling machines are made with high-quality parts which show their commitment to quality. They get these from top brands that ensure long lastingness, dependability and ease of maintaining them. By incorporating trusted names like Siemens, Delta and Schneider into its systems LevaPack assures high performance and less interruptions.

The frames for the machines from LevaPack are made using 1.5mm thick 304 stainless steel which is strong enough to withstand corrosion. Not only does this material extend the lifespan of the equipment, but it also makes cleaning easier, a necessity in food and beverage industries that have to maintain hygiene standards. Furthermore, all contact surfaces such as seaming heads and trays are manufactured from food grade 304 stainless steel hence ensuring safety as well as health regulations compliance.

By using quality components that are recognized internationally reduces the overall maintenance expenses incurred by customers. Availability of these parts is easily guaranteed since they can be quickly replaced whenever need arises hence avoiding time wastage through downtime. This increases production line efficiency while at the same time raises profits on investments for firms using LevaPack machinery.

LevaPack’s dedication to providing dependable high function equipment is highlighted by inclusion of first class components from world brands. Their can filling machines have been designed with great attention to detail ensuring they meet stringent requirements placed on them in modern manufacturing environments; hence clients are assured of peace of mind together with operational excellence.

Customization Expertise

The can filling machines made by LevaPack are customizable in many ways to meet the particular requirements of each customer. The fact is that different manufacturing conditions and products necessitate specific settings, and the company strives to ensure that it meets such needs.

LevaPack can change the structure of a machine for better integration with existing production lines. Due to this feature these devices can fit virtually any plant’s configuration scheme and work mode resulting in improved productivity and less disruption.

Electric components are also customized by LevaPack on request of clients. By selecting elements from reputable brands such as Siemens, Delta and Schneider, which are then adjusted according to peculiarities of use, performance and reliability of machinery are improved by LevaPack. Customized to this extent, every machine will work optimally when integrated into specific operating environments of customers.

Moreover, LevaPack produces tailor-made sealing molds for different sizes and types of cans. This helps clients who deal with various packaging types, thus ensuring proper sealing every time. Besides this, LevaPack has the capacity to adapt machine functionalities so as to handle unique packaging materials as well as product categories, i.e., liquids, solids or semi-solids.

A strong design and production process supports the commitment by LevaPack towards tailor-made solutions. All custom-built machines have an exact specification that makes them operate more efficiently while producing quality goods. Thus if they choose us businesses will enjoy having equipment designed exclusively for their use giving them competitive advantage over others.

Comprehensive Pre-Sales Support

LevaPack provides extensive pre-sales support to ensure that clients receive the most suitable solutions for their needs. The pre-sales team engages with customers to understand their detailed requirements, offering one-on-one service throughout the project.

From initial consultation to detailed solution design, LevaPack's team ensures that every aspect of the client's needs is addressed. This personalized approach helps build strong relationships and trust, ensuring that customers feel confident in their purchasing decisions.

Robust After-Sales Service

LevaPack does not stop at serving its customers after a sale has been made. A comprehensive after-sales service is provided including a one-year warrant for machines and dedicated technical support. In case there are any issues, the after sales team is available 24/7 providing quick replies and on-site assistance if required.

This robust system of support ensures that optimal performance of equipment is maintained by clients hence minimizing down time and maximizing productivity. Moreover, software upgrades as well as ongoing technical support are provided by LevaPack in order to keep these machines running smoothly and efficiently.

Choose LevaPack for Your Packaging Needs

In conclusion, some reasons why LevaPack remains a top manufacturer of can making machine include its exceptional production capacity, high quality components, customization expertise, comprehensive pre-sale supports service and strong post sale services . Businesses can improve their productivity rate, product quality thus claim more victories in marketplaces by choosing LevaPack.

When it comes to can packaging requirement; for innovation commitment to quality customer satisfaction count on Leva Pack? For more information visit their website at http://levapack.com/ or contact their team about how your business can receive positive changes through use of products from this company.

Media Contact

-

Company Name: LevaPack

-

Email: info@levapack.com

-

Phone: +86 189 2214 8881 / +86 189 2403 6188 / +86 158 1709 9018 / +86 20 3751 0321

-

Website: http://levapack.com/

-

Address: No. 764, East Chengao Avenue, Conghua District, Guangzhou City, Guangdong Province, China

Media Contact

Company Name: LevaPack

Email: Send Email

Phone: +86 20 3751 0321

Country: China

Website: levapack.com