-

Asahi Kasei’s new adsorbent, K-GIS zeolite, can remove CO2 from biogas, yielding high-purity methane gas (biomethane)

-

The trial separates CO2 and methane from biogas at a sewage treatment plant

-

Start of operation is estimated by the end of 2023

-

Capturing, utilizing or storing the separated CO2 by the system can lead to a carbon negative cycle in the future

Asahi Kasei, a diversified Japanese multinational company, and Kurashiki City today concluded an agreement to hold a trial to evaluate and demonstrate the performance of a biogas purification system (the System) at a sewage treatment plant in the city. Earlier in the day, the Mizushima Works of Asahi Kasei’s Production Center and Kurashiki City concluded a comprehensive partnership agreement for the realization of carbon neutrality in society. Advancing the demonstration trial for decarbonization is one of the provisions of the partnership.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20220915005100/en/

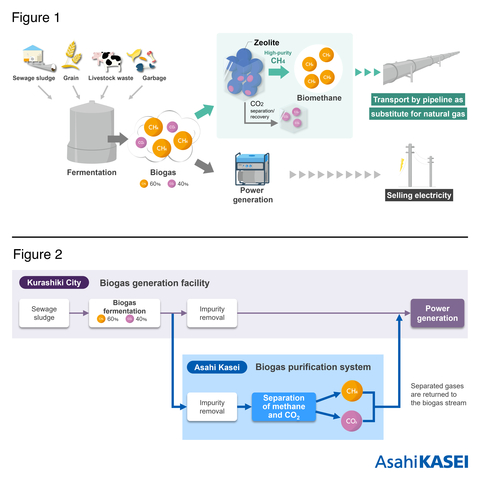

Figure 1 shows the flow of biogas. High-purity methane refinement is conducted mainly in Europe. Figure 2 shows the biogas flow at the Kojima Sewage Treatment Plant in Kurashiki City and the demonstration trial using the System. If biomethane production using this system is combined with carbon capture and utilization or storage (CCUS), the cycle would be carbon negative. This way of deriving both biomethane and CO2 from biogas is a promising development towards sustainability for multiple industries. (Graphic: Business Wire)

The System refines high-purity methane gas (biomethane) by removing CO2 from biogas utilizing Asahi Kasei’s newly developed adsorbent, K-GIS zeolite, which selectively adsorbs CO2. Unlike conventional adsorbents which adsorb methane together with CO2, K-GIS zeolite adsorbs almost no methane. This enables the System to efficiently separate and recover high-purity methane while recovering high-purity CO2.

Biogas from sewage sludge, garbage, etc., consists of approximately 60% methane and 40% CO2. While the use of biogas as a carbon-neutral fuel is rapidly expanding, it is also a source of biomethane as a substitute for natural gas in Europe and the U.S. (Figure 1)

In Kurashiki City, electricity is generated using biogas derived from sewage sludge at the Kojima Sewage Treatment Plant. The System will use a portion of this biogas for the demonstration trial. If biomethane production using the System is combined with carbon capture and utilization or storage (CCUS), the cycle would be carbon negative. In the demonstration trial, the separated gases are recombined to biogas as fuel for generating electricity. (Figure 2)

Schedule:

Fabrication of equipment in November 2022

Start of installation in May 2023

Start of operation at the end of 2023

Location:

Kojima Sewage Treatment Plant, Kurashiki, Okayama Prefecture, Japan

Roles of participants:

- Asahi Kasei will design, install, and operate the System, and evaluate and demonstrate its performance

- Kurashiki City will provide biogas generated from sewage sludge and the site for the demonstration trial

Commercialization of the System is expected around 2025 or 2026 following additional trials in countries or regions where biogas purification is performed. The technology will also be applied to CO2 separation and recovery from gases other than biogas.

About Asahi Kasei

The Asahi Kasei Group contributes to life and living for people around the world. Since its foundation in 1922 with ammonia and cellulose fiber businesses, Asahi Kasei has consistently grown through the proactive transformation of its business portfolio to meet the evolving needs of every age. With more than 46,000 employees around the world, the company contributes to a sustainable society by providing solutions to the world's challenges through its three business sectors of Material, Homes, and Health Care. Its Materials sector, comprised of Environmental Solutions, Mobility & Industrial, and Life Innovation, includes a wide array of products from battery separators and biodegradable textiles to engineering plastics and sound solutions. For more information, visit www.asahi-kasei.com.

Asahi Kasei is also dedicated to sustainability initiatives and is contributing to reaching a carbon neutral society by 2050. To learn more, visit https://www.asahi-kasei.com/sustainability/.

View source version on businesswire.com: https://www.businesswire.com/news/home/20220915005100/en/

Contacts

Company Contact North America:

Asahi Kasei America, Inc.

Jon Todd

39475 W. Thirteen Mile Road, Suite 201, Novi, MI 48377

E-mail: AKA-info@ak-america.com

Company Contact Europe:

Asahi Kasei Europe GmbH

Sebastian Schmidt

Fringsstrasse 17, 40221 Düsseldorf

Tel: +49 (0) 211-3399-2058

E-mail: sebastian.schmidt@asahi-kasei.eu