Novel doping method enables enhanced capacity and improved input/output performance at lower manufacturing cost using generally available materials and equipment

Asahi Kasei has begun licensing of technology for the design and manufacture of lithium-ion capacitors (LiCs) based on its proprietary lithium pre-doping technology1.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20230727511448/en/

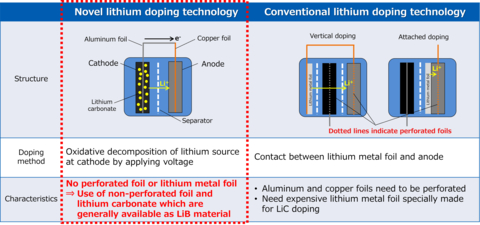

Diagram of Asahi Kasei's novel lithium doping technology (Graphic: Business Wire)

The novel proprietary doping method enables LiCs to be manufactured at lower cost with generally available materials and equipment which are used for manufacturing lithium-ion batteries (LiBs), while enabling the design and manufacture of LiCs with increased capacity and improved input/output performance.

The licensing includes not only Asahi Kasei's intellectual property related to LiC technology, but also technical expertise such as cell design and manufacturing with pilot equipment. By licensing its technology, Asahi Kasei expects to support licensees around the world to significantly reduce LiC development times and achieve low-cost LiC manufacture utilizing existing equipment.

Demand for energy storage devices is forecasted to continue rising due to the spread of electric mobility and increased use of renewable energy. The LiC is a next-generation energy storage device that uses the same material as an electric double layer capacitor (EDLC) for the cathode and the same material used as an LiB for the anode. As LiCs have higher input/output characteristics than LiBs, they are suited to fields where instantaneous power is needed, and can be quickly recharged. Also featuring long cycle life and high safety, LiCs are expected to be used in mobility applications such as electric trams and buses which charge at each stop instead of using power from overhead lines.

In the growing field of energy storage systems (ESS) for renewable energy such as solar and wind, it is possible to extend the service life of LiBs by using LiCs in conjunction to reduce the LiB charge/discharge load. This is expected to reduce both running costs and environmental impact through less frequent replacement of LiBs, generating less waste.

The conventional LiC manufacturing process requires expensive materials for pre-doping, such as perforated foil and lithium metal foil. Furthermore, as lithium metal is highly reactive and hazardous, additional costs are incurred to maintain a safe working environment.

Asahi Kasei developed a low-cost pre-doping method using inexpensive lithium carbonate as the source of lithium ions, eliminating the need for expensive materials such as perforated foil and lithium metal foil. With this novel doping method, lithium carbonate is included in the cathode and pre-doping is performed at initial charging, when nearly all of the lithium carbonate decomposes and lithium ions transfer to the anode. This not only allows the manufacture of LiCs using materials and equipment similar to those used in the manufacture of LiBs, but also enables capacity and input/output performance to be raised by a factor of 1.3 or more (compared to Asahi Kasei's conventional LiCs).

Asahi Kasei has already licensed this technology, and will continue offering it to other licensees in order to support further adoption and application development of the LiC as a next-generation energy storage device which contributes to the world's sustainability.

1 Lithium ions are pre-doped in the anode, keeping the anode potential lower than the electrolytic solution potential, allowing a larger energy density due to improved withstand voltage and increased capacitance of the capacitor itself compared to conventional EDLC.

About Asahi Kasei

The Asahi Kasei Group contributes to life and living for people around the world. Since its foundation in 1922 with ammonia and cellulose fiber business, Asahi Kasei has consistently grown through the proactive transformation of its business portfolio to meet the evolving needs of every age. With more than 48,000 employees worldwide, the company contributes to sustainable society by providing solutions to the world’s challenges through its three business sectors of Material, Homes, and Health Care. For more information, visit www.asahi-kasei.com.

View source version on businesswire.com: https://www.businesswire.com/news/home/20230727511448/en/

Contacts

Asahi Kasei Media Inquiries

Asahi Kasei America, Inc.

Christian OKeefe

E-mail: christian.okeefe@ak-america.com