Metals Acquisition Limited (NYSE: MTAL; ASX:MAC)

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20240422290327/en/

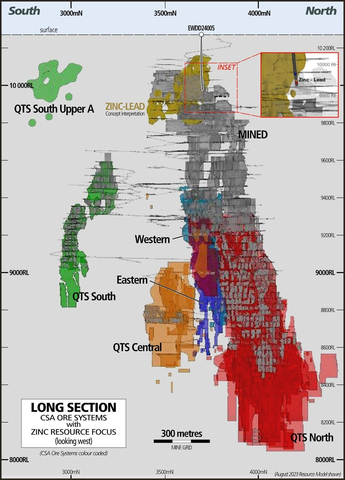

Figure 1 – Location of Zinc and Lead Mineralisation (Graphic: Business Wire)

Metals Acquisition Limited ARBN 671 963 198 (NYSE: MTAL; ASX: MAC), a private limited company incorporated under the laws of Jersey, Channel Islands (“MAC” or the “Company”) is pleased to release its Resource and Reserve Statement (as at 31 August 2023) (“R+R”) and 3 Year Production Guidance for the CSA Copper Mine in NSW.

In accordance with Item 1300 of Regulation S-K (17 CFR Part 229) (“S-K 1300”), all Mineral Resources are reported exclusive of Mineral Reserves.

Resource and Reserve Statement

Highlights from the R+R include:

- 67% increase in mine life to 11-years (end of 2034) based on Mineral Reserves only, compared to the 6-year mine life in the 2022 Resources and Reserves Statement

- 64% increase in contained copper (“Cu”) after replacement of depletion to 0.5Mt in Mineral Reserves (Refer Table 3 for breakdown) at an average grade of 3.3% Cu

- Measured and Indicated Mineral Resources increased to 229 ktonnes of Cu from zero in the prior (Refer Table 2 for breakdown) at an average grade of 4.9% Cu

- An additional 184 ktonnes of Cu in the Inferred Mineral Resources, an approximate 5% reduction on the prior year as Inferred material was promoted to Measured and Indicated Categories

- 83% increase in contained Cu after replacement of depletion in the Measured and Indicated Resources categories

- 2023 Mineral Reserve only extends 95m vertically below the current decline position

- Above increases have come after only ten months of ownership and based on data from two and a half months post-closing of the acquisition with the effective date for the R+R being 31 August 2023

- All deposits (other than QTSSU-A (feasibility study), are open in at least one direction and drilling is continuing to further increase the R+R, subject to exploration success and economic factors

The effective date for the R+R is 31 August 2023 and as such, any new information received after that time has not been incorporated into the R+R at this stage.

Work is continuing on updating the mine plans as new information is received and importantly following on from the completion of MAC’s dual listing on the ASX and public offer that raised A$325 million of equity the Company is pushing forward with its growth capital spending to further optimise the mine plan.

MAC CEO, Mick McMullen commented “Whilst this Resource and Reserve Statement is a snapshot in time based on information available back in August 2023, it does validate our belief that the CSA Copper Mine can be a long-life asset. Importantly, despite the near doubling of the Mineral Reserves and a 67% increase in the mine life, we still have 4.7Mt @ 4.9% Cu (230Kt Cu) in the Measured and Indicated Category and 3.3Mt @ 5.5% Cu (180Kt Cu) in the Inferred Category that are not included in the Mineral Reserves and work is underway to convert these to our Mineral Reserve estimates in the future.

We have always believed that the CSA Copper Mine would have a long future and this Resource and Reserve Statement upgrade confirms this and also provides us with the underlying Mineral Resource base from which to put long term plans in place that simply hasn’t been possible for the last generation when the mine has always had a 5 to 6-year reserve mine life ahead of it. There has perhaps been a view by some observers that the CSA Copper Mine has a relatively short mine life, with today’s Resource and Reserve Statement announcement we can dispel that view and now focus on mining more Copper faster and at lower costs. We are but ten months into our ownership of the mine and it has a lot of potential to be uncovered still.”

Three Year Production Guidance

Based on the updated R+R, the Company is providing the following production guidance for the next three years:

Table 1 - CSA Copper Mine Production Guidance

2024 |

2025 |

2026 |

||||

|

Low Range |

High Range |

Low Range |

High Range |

Low Range |

High Range |

Cu Production (tonnes) |

38,000 |

43,000 |

43,000 |

48,000 |

48,000 |

53,000 |

This three-year production guidance is based primarily on Mineral Reserves but also on measured and indicated Mineral Resources (as at 31 August 2023) and, given that all the deposits are open and a large drill program is underway, MAC considers it likely that there will be changes over the relevant period as the Company’s overall plan to continue operational and production improvement continues to develop.

The 42% and 64% increase in contained Cu after replacement of depletion for Mineral Resources and Mineral Reserves respectively in the R+R has come after ten months of ownership and based on data from two and a half months post-closing of the acquisition.

The CSA Copper Mine has been producing for almost 60 years with very limited exploration away from the known deposits and there is potential to further optimise this production plan.

As discussed below, exploration in the top 850m of the deposit is just starting and initial results highlight strong potential to open additional mining fronts.

Mineral Resources

The Mineral Resources have been updated based on data to 31 August 2023 and allowing for depletion to that date. Total S-K 1300 Mineral Resources are shown in Table 2 below:

Table 2- CSA Copper Mine Mineral Resources

System

|

Resource Category |

Tonnes Mt |

Cu % |

Cu Metal kt |

Ag g/t |

Ag Metal Moz |

|

|

|

|

|

|

|

All Systems |

Measured |

3.3 |

5.6 |

182 |

19 |

2.0 |

|

Indicated |

1.4 |

3.4 |

47 |

6 |

0.3 |

|

Meas + Ind |

4.7 |

4.9 |

229 |

15 |

2.3 |

|

Inferred |

3.3 |

5.5 |

184 |

21 |

2.2 |

|

Total |

8.0 |

5.2 |

413 |

18 |

4.5 |

Notes:

- Mineral Resources are reported as of 31 August 2023;

- Mineral Resources are reported in accordance with S-K 1300, including with respect to defined terms;

- Mineral Resources are reported exclusive of Mineral Reserves;

- The Qualified Person who prepared the statement is Mike Job, of Cube Consulting Pty Ltd;

- Price assumptions used in the estimation include US$8,279/t of copper and US$22.60/troy ounce (“oz”) of silver; in line with long term Broker Consensus forecast copper pricing as at August 8, 2023;

- Geological mineralization boundaries defined at a nominal 2.5% Cu cut off for high grade lenses, and 1.5% Cu for the lower-grade halo. Resources reported above a 1.5% Cu cut-off grade;

- Costs assumptions underlying cut-off grade calculation include US$78/t ore mined, US$20/t ore milled and US$21/t G&A ore milled;

- Metallurgical recovery assumptions used in the estimation were 97.5% copper recovery and 80% silver recovery;

- Mineral Resources reported as dry, raw, undiluted, in-situ tonnes; and

- Figures are subject to rounding.

As discussed above, not only has total contained Cu in Mineral Resources increased by 42%, the Measured and Indicated portions available for Mineral Reserve conversion has increased by 83%. This is a result of increased drilling and the inclusion of level mapping data where levels have been developed through the deposits and not previously been included in the Mineral Resource.

Overall grade has reduced from 5.3% Cu in the 2022 R+R to 4.9% in the 2023 R+R which is predominately a result of the inclusion of 2.2Mt of material between the new cut-off grade of 1.5% Cu and the previous cut-off grade of 2.5% Cu. In terms of contained Cu this material had a relatively small impact to the overall change, with the larger changes coming from the inclusion of new drilling and level mapping data.

As evidenced by the recent drill results released by the Company,1 including 19.2m @ 10.4% Cu in UDD23025 and 16m @ 10.5% Cu in UDD23024 these deposits are characterised by high grade lodes that have a long vertical extent that project well past the 2023 R+R.

In addition, whilst the mine is currently a producer of high quality Cu concentrates, it did start life as a high grade zinc (“Zn”) mine. As seen in the recently released QSD060 result of 4.3m @ 14.2% Zn, 3.9% Pb and 0.8% Cu the shallower portions of the deposits do host significant Zn mineralisation that is yet to be modelled.

The current R+R starts at a depth of 850m below surface (except for the small QTSS Upper-A deposit) as the data for this area has not historically been in the digital database. A large amount of historical data is available for these shallower portions of the mine and approximately 70% of this has now been digitized. None of this information has been included in the 2023 R+R. Drilling is underway to verify the presence of the mineralisation included in this historical dataset, with the first hole intercepting Zn and Cu massive sulphides as predicted by the historical data at a depth below surface of approximately 330m.

This mineralisation is vertically extensive and occurs adjacent to existing mine development with the interval in EWDD24005 located 30m from existing development as seen in Figure 1. Figure 2 shows the core from the most recent drilling in this area that was targeted at the indicated position of this mineralisation based on the historical data.

Figure 1 – Location of Zinc and Lead Mineralisation

Figure 2 - Massive Zn and Cu Mineralisation in EWDD24005

Mineral Reserves

The Mineral Reserves have been updated based on data to 31 August 2023 and allowing for depletion to that date.

Total S-K 1300 Mineral Reserves are 14.9Mt @ 3.3% Cu and 13 g/t Ag and are shown in Table 3 below:

Table 3 - CSA Copper Mine Mineral Reserves

CSA Copper Mine |

Proved |

Probable |

Proved and Probable |

M tonnes |

8.3 |

6.6 |

14.9 |

Cu % |

3.5 |

3.1 |

3.3 |

Contained Cu ktonnes |

293 |

201 |

494 |

Ag g/t |

14 |

11 |

13 |

Contained Ag M oz |

3.9 |

2.4 |

6.2 |

Notes:

- Mineral Reserves are reported as of 31 August 2023 and are reported using the definitions in S-K 1300;

- The Qualified Person who prepared the statement is Jan Coetzee, an officer of MAC, the Registrant’s Australian subsidiary;

- Price assumptions used in the estimation include US$8,279/t of copper and US$22.60/troy ounce (“oz”) of silver; in line with long term Broker Consensus forecast copper pricing as at August 8, 2023;

- Mineral Reserves reported as dry, diluted, in-situ tonnes using a Stope breakeven cut-off grade of 2.2% Cu for 2024 to 2026 and a cut-off-grade of 1.65% for the remaining periods and a Development breakeven cut-off grade of 1.0% Cu;

- Costs assumptions underlying cut-off grade calculation include US$78/t ore mined, US$20/t ore milled and US$21/t G&A ore milled;

- Metallurgical recovery assumptions used in the estimation were 97.5% copper recovery and 80% silver recovery; and

- Figures are subject to rounding.

Ore Reserves were estimated at a Cu price of US$8,279/t Cu, which compares to a spot price of US$9,905/t Cu as at 20 April 2024.

Mineral Reserve grade at 3.3% Cu is down from 4% Cu in the prior year which is a reflection of the lower cost base that the mine is now operating under. This is as a result of reduced mine site operating costs and offsite charges. Cut-off grade is variable based on the ability to mine at higher rates once the Return Air Rise (“RAR”) are complete and ranges from 2.2% Cu near term to 1.65% Cu for the longer term.

The mine plan strategy is somewhat determined by the requirement for additional RAR ventilation at the bottom of QTSN, during which time the mine plan mines the higher grade core. Once the RAR system is in place then the mine plan reverts to a more bulk tonnage model given the large excess processing plant capacity at the mine. At elevated Cu prices the goal is to maximise Cu production where possible and to defer any lower grade material to the back end of the mine plan.

Figure 3 illustrates the changes in the Mineral Reserves from the prior year.

Figure 3 – CSA Copper Mine Contained Cu in Reserve Changes 2022 to 2023

Spatially, the location of the 2023 Mineral Reserve compared to the 2022 Mineral Reserve is shown in Figure 4 below. The bulk of the increases have been in QTSN where the deposit has been increasing in strike length and QTSC where drilling has expanded the lateral and vertical extend of the deposit.

All deposits are open and as seen in Figures 5 and 6 below the Mineral Reserves terminate at RL’s based on drill density with the deposits extending significantly past the 2023 Mineral Reserves.

Figure 4 - Location of the 2023 Mineral Reserve compared to the 2022 Mineral Reserve

The bulk of the Mineral Reserves (84% of total contained Cu) are from the QTSN and QTSC deposits and Figures 5 and 6 illustrate the location of the Mineral Reserves compared to the various resource classifications.

Figure 5 - Location of Mineral Reserves and Mineral Resource Classification - QTSN

Mineral Reserves in QTSN have been extended to the 8300mRL, with current stoping active on the 8430m RL and the decline at the 8395mRL. As such, the current 11 year mine life is only mining a further 95m vertically below the bottom of the decline position at the end of March 2024.

Figure 6- Location of Mineral Reserves and Mineral Resource Classification – QTSC

The material R+R increase from the R+R at the time of purchase will now enable the Company to optimise mining rates with a view to producing more Cu sooner given the potential for even longer mine life subject to converting the non Mineral Reserve material. This will also be instrumental in right sizing the capital structure of the Company.

Life of Mine (“LOM”) Plan

The LOM plan is based on Mineral Reserves only and on data from the end of August 2023. Several of the deposits being mined or planned to be mined still contain elevated levels of Inferred Resources that are not included in the LOM under both the JORC and S-K 1300 Codes.

Table 4- CSA Copper Mine Life of Mine Plan

2024 |

2025 |

2026 |

2027 |

2028 |

2029 |

2030 |

2031 |

2032 |

2033 |

2034 |

|

Tonnes - Total Ore (t) |

1,068,000 |

1,286,000 |

1,399,000 |

1,399,000 |

1,399,000 |

1,397,000 |

1,394,000 |

1,396,000 |

1,399,000 |

1,390,000 |

1,034,000 |

Grade - Cu (%) |

3.6% |

3.3% |

3.6% |

3.5% |

3.4% |

3.4% |

3.1% |

3.0% |

3.1% |

2.8% |

3.2% |

Grade - Ag (g/t) |

16 |

12 |

14 |

13 |

13 |

13 |

12 |

12 |

13 |

11 |

14 |

Metal - Cu (t) |

38,000 |

43,000 |

50,000 |

49,000 |

48,000 |

47,000 |

43,000 |

42,000 |

42,000 |

39,000 |

33,000 |

Metal - Ag (oz) |

537,000 |

499,000 |

639,000 |

588,000 |

565,000 |

573,000 |

522,000 |

542,000 |

568,000 |

504,000 |

481,000 |

JORC

MAC is subject to the reporting requirements of both the Securities Exchange Act of 1934 (US) and applicable Australian securities laws (including the ASX Listing Rules), and as a result, has separately reported its Mineral Reserves (referred to as ore reserves for the purpose of the Australasian Joint Ore Reserve Committee Code, 2012 edition (JORC)) and Mineral Resources according to the standards applicable to those requirements. U.S. reporting requirements are governed by S-K 1300, as issued by the SEC. Australian reporting requirements are governed by JORC. Both sets of reporting standards have similar goals in terms of conveying an appropriate level of consistency and confidence in the disclosures being reported, but the standards embody slightly different approaches and definitions. All disclosure of Mineral Resources and Mineral Reserves in this report are reported in accordance with S-K 1300. For JORC and ASX Listing Rule compliant disclosure of mineral reserves (Ore Reserves for the purpose of JORC) and mineral resources, please see the Company’s separate release to be released on ASX on 23 April 2024. In order to comply with SEC requirements the Company expects to lodge an S-K 1300 Technical Report with the SEC in the near term.

Conference Call

The Company will host a conference call and webcast to discuss the Company’s updated Reserve and Resource statement on Monday, April 22, 2024 at 7:00 pm (New York time) / Tuesday, April 23, 2024 at 9:00 am (Sydney time).

Details for the conference call and webcast are included below.

Webcast

Participants can access the webcast at the following link https://events.q4inc.com/attendee/950238182

Conference Call

Participants can dial into the live call by dialling 800-274-8461 or +1-203-518-9783 and providing the conference ID ‘METALS’.

Replay

The conference call will be available for playback until July 22, 2024 and can be accessed by dialling 1-888-567-0047 or +1-402-220-6953 or visiting the webcast link https://events.q4inc.com/attendee/950238182.

This announcement is authorised for release by the Board of Directors.

QUALIFIED PERSON STATEMENTS

Mineral Resources

The information in this announcement that relates to the Company’s Mineral Resources is based on information compiled by Mike Job, a Qualified Person for the purpose of S-K 1300, who is a Fellow of the Australian Institute of Mining and Metallurgy. Mr Job is employed by Cube Consulting Pty Ltd. Mr Job . Mr Job consents to the inclusion in this announcement of the matters based on this information in the form and context in which it appears.

Mineral Reserves

The information in this announcement that relates to the Company’s Mineral Reserves is based on information compiled by Jan Coetzee, a Qualified Person for the purpose of S-K 1300, who is a Member of the Australian Institute of Mining and Metallurgy. Jan Coetzee is employed by Metals Acquisition Corp. (Australia) Pty Ltd (being a wholly owned subsidiary of Metals Acquisition Limited). Mr Coetzee consents to the inclusion in this announcement of the matters based on this information in the form and context in which it appears.

About Metals Acquisition Limited

Metals Acquisition Limited (NYSE: MTAL; ASX:MAC) is a company focused on operating and acquiring metals and mining businesses in high quality, stable jurisdictions that are critical in the electrification and decarbonization of the global economy.

Forward Looking Statements

This release has been prepared by Metals Acquisition Limited (“Company” or “MAC”) and includes “forward-looking statements.” The forward-looking information is based on the Company’s expectations, estimates, projections and opinions of management made in light of its experience and its perception of trends, current conditions and expected developments, as well as other factors that management of the Company believes to be relevant and reasonable in the circumstances at the date that such statements are made, but which may prove to be incorrect. Assumptions have been made by the Company regarding, among other things: the price of copper, continuing commercial production at the CSA Copper Mine without any major disruption, the receipt of required governmental approvals, the accuracy of capital and operating cost estimates, the ability of the Company to operate in a safe, efficient and effective manner and the ability of the Company to obtain financing as and when required and on reasonable terms. Readers are cautioned that the foregoing list is not exhaustive of all factors and assumptions which may have been used by the Company. Although management believes that the assumptions made by the Company and the expectations represented by such information are reasonable, there can be no assurance that the forward-looking information will prove to be accurate.

MAC’s actual results may differ from expectations, estimates, and projections and, consequently, you should not rely on these forward-looking statements as predictions of future events. Words such as “expect,” “estimate,” “project,” “budget,” “forecast,” “anticipate,” “intend,” “plan,” “may,” “will,” “could,” “should,” “believes,” “predicts,” “potential,” “continue,” and similar expressions (or the negative versions of such words or expressions) are intended to identify such forward- looking statements. These forward-looking statements include, without limitation, MAC’s expectations with respect to future performance of the CSA Copper Mine. These forward-looking statements involve significant risks and uncertainties that could cause the actual results to differ materially from those discussed in the forward-looking statements. Most of these factors are outside MAC’s control and are difficult to predict. Factors that may cause such differences include, but are not limited to: the supply and demand for copper; the future price of copper; the timing and amount of estimated future production, costs of production, capital expenditures and requirements for additional capital; cash flow provided by operating activities; unanticipated reclamation expenses; claims and limitations on insurance coverage; the uncertainty in Mineral Resource estimates; the uncertainty in geological, metallurgical and geotechnical studies and opinions; infrastructure risks; and other risks and uncertainties indicated from time to time in MAC’s other filings with the SEC and the ASX. MAC cautions that the foregoing list of factors is not exclusive. MAC cautions readers not to place undue reliance upon any forward-looking statements, which speak only as of the date made. MAC does not undertake or accept any obligation or undertaking to release publicly any updates or revisions to any forward-looking statements to reflect any change in its expectations or any change in events, conditions, or circumstances on which any such statement is based.

More information on potential factors that could affect MAC’s or CSA Copper Mine’s financial results is included from time to time in MAC’s public reports filed with the SEC and the ASX. If any of these risks materialize or MAC’s assumptions prove incorrect, actual results could differ materially from the results implied by these forward-looking statements. There may be additional risks that MAC does not presently know, or that MAC currently believes are immaterial, that could also cause actual results to differ from those contained in the forward-looking statements. In addition, forward-looking statements reflect MAC’s expectations, plans or forecasts of future events and views as of the date of this communication. MAC anticipates that subsequent events and developments will cause its assessments to change. However, while MAC may elect to update these forward-looking statements at some point in the future, MAC specifically disclaims any obligation to do so, except as required by law. These forward-looking statements should not be relied upon as representing MAC’s assessment as of any date subsequent to the date of this communication. Accordingly, undue reliance should not be placed upon the forward-looking statements.

Appendix 1 – CSA Copper Mine Mineral Resources and Mineral Reserves Mineral Resource Statement

Mineral Resources

The following summary of all information material to understanding the reported estimates of Mineral Resources in relation to the following matters is provided.

Geology and geological interpretation

The CSA deposit is located within the Cobar mineral field, in the Cobar Basin. Mineralisation is hosted in the Silurian-age CSA Siltstone, a member of the Amphitheatre Group of the Cobar Supergroup sequence of rocks and is associated with zones of deformation and shearing. The CSA Siltstone consists of a sequence of rhythmic bedded siltstones and sandstones. The rock sequence was structurally deformed during the development of the Cobar Basin in the early Devonian period.

Interpretation of the wireframes is based on geological mapping in the mine, drill core logging, and the structural model that has been developed over time. CSA used a threshold of 2.5% Cu to guide the interpretation of the high-grade lenses. These wireframes are generally constructed manually in Datamine software. For the QTSS Upper A however, the mineralised domains are constructed using an implicit modelling method to create the wireframes (using the Datamine vein modelling function). There is a new lower grade domain which covers the five systems for QTSN, QTSC, QTSS, Eastern and Western. These domains use a value of 1.5% Cu and form a lower-grade halo to the high-grade lenses. The construction of these lower-grade halo domains is different from the manual domain interpretations traditionally used for the high-grade lenses. In this case, a categorical indicator is applied to one metre down-hole composited drill sample assays at 1.5% Cu, and this indicator is estimated by Ordinary Kriging into a block model. The low-grade halo domain wireframe is then created at an indicator probability value of 0.4.

Sampling and sub-sampling techniques

Half core samples are mostly 1m in length with sample weights averaging 1.9kg. The cutting and sampling process is carried out at CSA Mine.

The sampling procedures includes interval checks, cutting intervals, sampling intervals, inserting standards and blanks, sampling duplicates, weighing samples and dispatching samples. All parts of the core processing cycle are tracked and recorded electronically.

Drilling techniques

Drilling comprised mostly NQ and NQ2 diamond drill holes using standard tube although in 2023 all underground drilling was NQ3 size. Minor sampling from HQ, BQ, LTK48 and LTK60 sized diamond core holes.

Criteria for classification

Mineral Resource Classification takes into account: location of mine development, drill spacing, grade continuity, search criteria, and copper Kriging metrics. In summary:

- Measured has a diamond drill spacing of approximately ≤20m north-south by 37.5m vertical for QTS North and 20m north-south by 20m vertical for other systems.

- Indicated has a diamond drill spacing of approximately ≤40m north-south by 70m vertical (QTS North) and 40m north-south by 40m vertical (all other systems).

- Inferred has a diamond drill spacing of approximately ≥40m north-south by 70m vertical (QTS North) and 40m north-south by 40m vertical (all other systems). Drill density is sufficient to give confidence that the lens persists down plunge/dip.

Sample analysis method

Samples for assay are sent to the ALS Laboratory in Orange, NSW. All samples are assayed using ALS’ Assay Procedure – ME-OG46, Ore Grade Elements by Aqua Regia Digestion Using Conventional ICP-AES Analysis for a list of elements including Cu, Ag, Pb, Zn, Fe and S.

Estimation methodology

Grade estimation is by Ordinary Kriging using 1m composites within hard boundary domains defined using a 2.5% Cu threshold width a lower-grade halo around the high-grade zones using a 1.5% Cu threshold. 1m Cu composites are not top-cut as extreme values are considered real and have been accounted for by geological domain boundaries. However, Ag composites are top-cut due to extreme values for certain geological domains.

Cut-off grade(s) including the basis for the selected cut-off grade(s)

Mineral resources are reported above a 1.5 Cu (%) cut-off. The high-grade mineralisation interpretation is based on geology and represents a natural 2.5% Cu cut-off.

Mining and metallurgical methods and parameters (other material modifying factors considered to date)

The mineral resource interpretations are steeply plunging and ideal for the long hole stoping methods adopted at CSA. Stope size and standard mining block units also influenced parent block size selection.

Copper processing recoveries at CSA are typically 96.8 - 98.5% producing a concentrate grade of approximately 25.98% Cu.

Mineral Reserves

The following is a summary of all information material to understanding the reported estimates of Mineral Reserves in relation to the following matters:

Material Assumptions

The material assumptions used in preparation of this Mineral Reserve are as follows:

- 2023 Mineral Resource estimate;

- Heading advance and stoping rates in-line with historical performance;

- Modifying factors are in line with historical data and industry norms;

- Mine design principles (ie: strike length, transverse width, level intervals, etc.) are in line with currently utilised mining methods and design principles;

- No material changes to metallurgical recoveries are expected;

- Production gradually ramps up from 1.1 Mtpa to 1.4 Mtpa at a rate of approximately 0.1 Mtpa per year; and

- Price assumptions used in the estimation include US$8,279/t of copper and US$22.60/troy ounce (“oz”) of silver; in line with long term Broker Consensus forecast copper pricing as at August 8, 2023;

- Mineral Reserves reported as dry, diluted, in-situ tonnes using a Stope breakeven cut-off grade of 2.2% Cu for 2024 to 2026 and a cut-off-grade of 1.65% for the remaining periods and a Development breakeven cut-off grade of 1.0% Cu; and

- Costs assumptions underlying cut-off grade calculation include US$78/t ore mined, US$20/t ore milled and US$21/t G&A ore milled.

Criteria for Classification

The criteria used for classification, including the classification of the Mineral Resources on which the Mineral Reserves are based and the confidence in the modifying factors applied are as follows:

- Mineral Reserves were classified based on the ration of contained Measured and Indicated Mineral Resources;

- Measured Mineral Resources are converted to Proved Mineral Reserves, and Indicated Mineral Resources are converted to Probable Mineral Reserves;

- Any contained Inferred Mineral Resource is considered as waste;

- No Measured Mineral Resource has been downgraded to Probable Mineral Reserve; and

- Appropriate modifying factors have been applied based on historic performance and in line with industry norms.

Mining Methodology

The mining method selected and other mining assumptions, including mining recovery factors and mining dilution factors are as follows:

- The mining method used is sub-level open stoping, primary in the form of top-down, transverse stoping with cemented paste backfill. There is also longitudinal and modified Avoca stoping. Some areas are mined bottom-up. There is significant operating experience with these mining methods at CSA Mine;

- Recovery factors used are 99% for transverse stopes, 91% for longitudinal stopes, and 97% for modified Avoca stopes; and

- Dilutions factors used are 13% for transverse stopes, 20% for longitudinal stopes, and 26% for modified Avoca stopes.

Processing Method

The processing method selected and other processing assumptions, including the recovery factors applied and the allowances made for deleterious elements are as follows:

- On-site processing is using a conventional flotation concentrator which has been in operation since 1965. This produces concentrate which is sent off-site for smelting and refining to produce copper cathode;

- Copper processing recoveries are expected to average 97.5% - 98.5% and silver recoveries are expected to be 80%; and

- Any deleterious elements encountered are expected to be maintained below penalty levels by managing the ore feed blend, if required.

Basis for cut-off grade(s) or quality parameters applied

The basis for cut-off grade(s) or quality parameters applied are as follow:

-

A stope break-even cut-off grade of 1.65% Cu was calculated:

- Based on historical operating costs with gradually applied efficiency improvements reasonably anticipated by MAC; and

- Copper price of US$8,250 per tonne and silver price of 21.70 per troy ounce; and

- A stope cut-off grade of 2.20% Cu was applied prior to end-of-year 2026 with 1.65% Cu applied thereafter. This was to manage metal production during a period of increasing mining rate.

Estimation Methodology

The procedure used (estimation methodology) in the preparation of the Mineral Reserve are as follows:

- Mineable shapes were generated using Deswik.SO software;

- Stope dimensions are based on existing operating practices;

- These mineable shapes were re-evaluated against the various Mineral Resource models with all inferred material grades set to zero Shapes were then manually refined removing stopes below cutoff, in isolated areas, adding pillars as required, and removing shapes which could not practically be mined due to proximity to voids or infrastructure;

- Cut-offs were evaluated post application of modifying factors;

- Development designs and sequencing were completed for all areas to generate a Deswik schedule;

- The variable cut-off grade was applied, and where possible stope below the variable cutoff were delayed to later in the mine life; and

- The schedule was levelled based on production and development constraints to generate the Mineral Reserve Schedule.

Material modifying factors

Material modifying factors, including the status of environmental approvals, mining tenements and approvals, other government factors and infrastructure requirements for selected mining methods and for transportation to market are as follows:

-

CSA Mine is an operating mine and holds Consolidated Mining Lease 5 (CML5) and two small mining purposes leases, 1093 and 1094 (MPL1093, MPL1094):

- CML5, MPL1093, and MPL 1094 are due to expire in 2028, 2029, and 2029 respectively; and

- All required government approvals and licenses for operation are in place;

- All materially required mining infrastructure is in place on-site for the purposes of mining, processing, and shipment of concentrate to market; and

- The mining methods used for the Mineral Reserve estimate are currently in use at CSA mine with extensive operating history.

____________________

1 Please refer to MAC’s Announcement dated 19 March 2024 titled ‘CSA Copper Mine Reports Drill Results’.

View source version on businesswire.com: https://www.businesswire.com/news/home/20240422290327/en/

Contacts

Mick McMullen

Chief Executive Officer

Metals Acquisition Limited.

investors@metalsacqcorp.com

Morne Engelbrecht

Chief Financial Officer

Metals Acquisition Limited