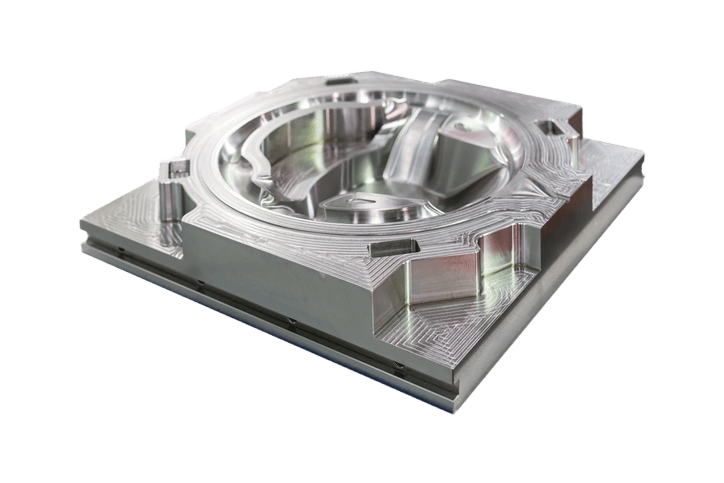

The advanced 5-axis technology creates intricate contours and tight tolerances that are essential for high-performance aerospace applications. This capability enhances the precision of each component and reduces production times and material costs, offering significant value to clients.

In addition to 5-axis CNC machining, Cutter Innovations boasts a sophisticated Wire EDM (Electrical Discharge Machining) shop. This technology enables the production of highly detailed and precise parts, particularly those made from hard and high-temperature resistant materials commonly used in aerospace engineering. The Wire EDM process complements the company’s CNC capabilities, ensuring that even the most challenging materials and designs are handled precisely.

Its comprehensive inspection processes further demonstrate Cutter Innovations’ commitment to quality. Utilizing cutting-edge Zeiss scanning Coordinate Measuring Machines (CMMs) and programmable vision systems, the company ensures that every part meets stringent quality and repeatability standards. These meticulous inspection methods, conducted within a temperature-controlled environment, guarantee that all aerospace components adhere to the exact specifications required by the industry.

The company’s engineering team, composed of Certified SolidWorks Professionals, plays a pivotal role in product development and prototyping. Their expertise in solid modeling and Design for Manufacturing and Assembly (DFMA) enables the seamless transition from concept to production. By collaborating closely with clients, Cutter Innovations ensures that each project benefits from innovative design solutions and efficient manufacturing processes while protecting intellectual property throughout development.

With a spacious 12,000-square-foot manufacturing area, Cutter Innovations continues expanding its technological capabilities to better serve its customers. Adopting lean manufacturing principles and 5S methodologies ensures maximum efficiency and machine uptime, allowing the company to handle both prototype and production runs with ease. This expansive facility is a testament to Cutter Innovations’ dedication to growth and continuous improvement in the precision machining sector.

Cutter Innovations’ transparent approach to business is evident in its open-book bidding process. By sharing detailed costing information with clients, the company fosters trust and ensures complete transparency during the quoting process. This openness and the ability to return quotes within 48 hours for prototypes and short-run production work make Cutter Innovations a preferred partner for many aerospace machine shops.

Owned and operated by Mike and Ruthie Swartzlander, Cutter Innovations embodies a passion for quality and strong client relationships. Their background in engineering from the Colorado School of Mines and extensive experience in the aerospace and medical industries have shaped the company’s focus on delivering high-end machining services without the high costs and long lead times typically associated with precision manufacturing.

Media Contact

Company Name: Cutter Innovations

Contact Person: Mike

Email: Send Email

Country: United States

Website: https://www.cutterinnovations.com